Blog Post

How to Better Manage Engineer To Order Capacity

AJ Ansari • March 1, 2024

If engineer-to-order (ETO) manufacturers want to keep customers happy with accurate lead times

, they need to understand production load and manufacturing capacity constraints. Only with a true picture of your resource capacity can you make and fulfill promises to customers. But doing so is easier said than done if you’re using traditional project management methods or if you lack the right technology.

Below, we look closer at why visualizing capacity is so tricky in ETO organizations, and we unveil the solution that gives managers, engineers, and sales people the visibility they need to effectively plan and deliver the right lead times.

The Challenge with Understanding ETO Capacity

A few roadblocks lie between ETO managers and an accurate view of their capacity. For starters, ETO manufacturers may have multiple projects going on at once. Some of the same human resources might be involved in any number of those projects, muddying a manager’s ability to see where that person’s capacity will be devoted in coming months. Without an open line of visibility and communication into all ETO projects, stakeholders are also in the dark about capacity. They might not know about certain projects that are set to consume certain resources in the organization—causing them to give customers lead times without the right data.

There’s also a vendor-related component to this challenge. ETO organizations might run some manufacturing internally, requiring them to have visibility into their own capacity, but they also may source parts through vendors. Communication is essential for grasping the capacity of your vendors so you can understand production load and related constraints. Will you have to bring on additional machines or temporary employees to extend your capacity? Will you have to pay your vendor expediting fees to get a project done on time? These questions and more impact not just your ability to make promises to customers but to predict costs as well .

Data-Sharing and Communication Keep Capacity Clear

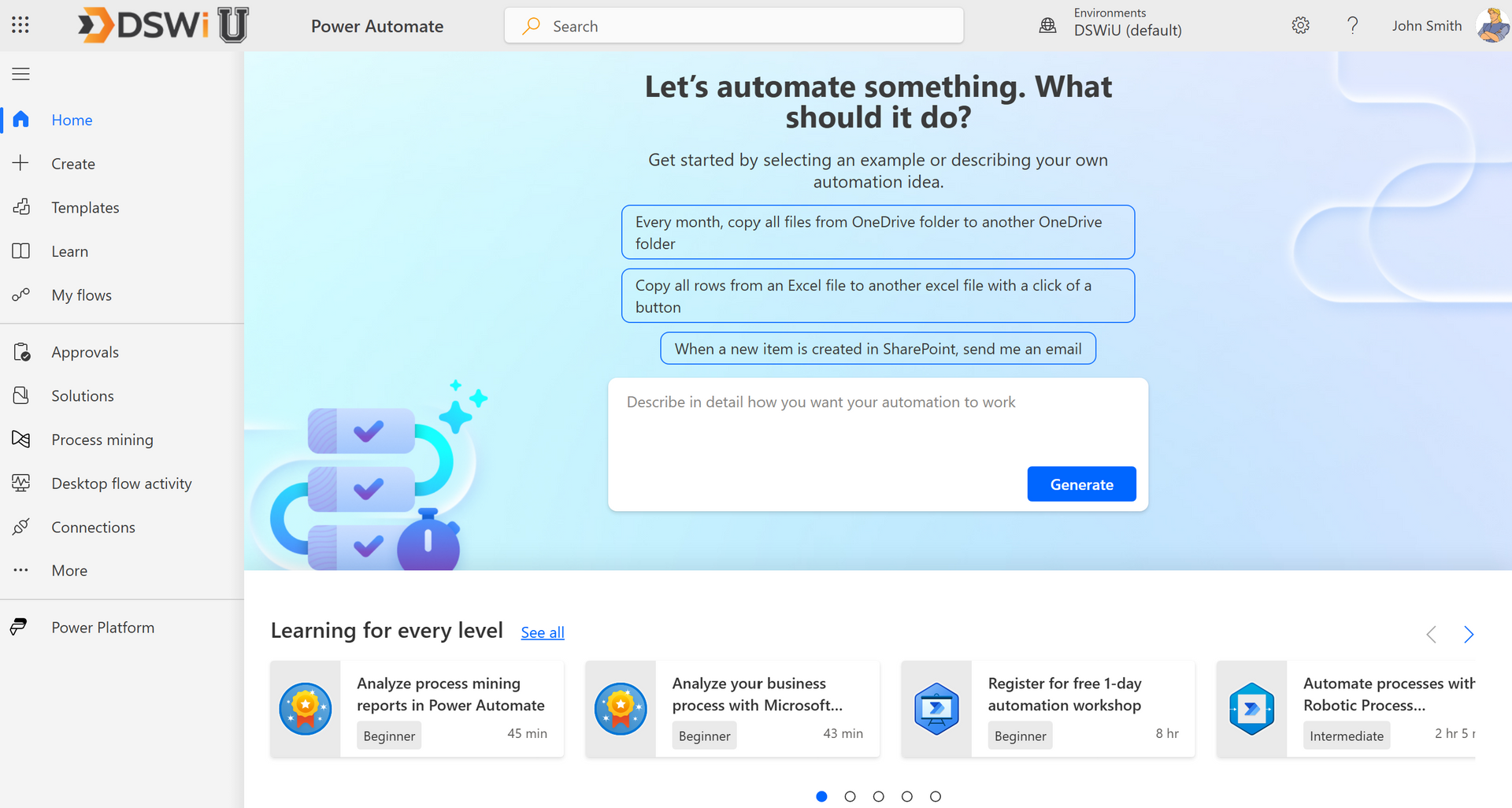

ETO manufacturers need to use an enterprise resource planning (ERP) system properly to address this challenge. Solutions like Microsoft Dynamics Business Central offer basic functionality, but only with the right extensions and software expertise can ETO companies truly gain insight into resource capacity. Having the right data in your ERP system—and making it shareable across your entire value chain—helps all parties visualize production load and capacity.

With the right technology and data-sharing practices, a production manager is able to see what their manufacturing capacity will be for six months, for example, and share that information with stakeholders. They can provide an estimate to an engineer and a sales person so the latter can give a delivery date to a customer based on real data. Software extensions that fill gaps in ERP systems like Business Central are essential for keeping tabs on capacity constraints so managers can make data-informed decisions about resources and timelines.

It's also wise for ETO organizations to work with an expert who knows the ins and outs of ERP systems and the relevant extensions so they can rest assured their data is set up properly. You need to ensure information like production orders and purchase orders are in your system correctly in order to leverage the functionality that lets you see load and capacity on a calendar basis. Using a seasoned partner for ERP set-up will get you on the right path.

Let DSWi Shine a Light into Your Production Capacity

DSWi has decades of experience in ETO, and we understand your industry-specific challenges. We’ve worked in ETO environments and organizations across oil and gas and other sectors. We’ve seen the problems that arise from a lack of visibility into capacity, so we’ve devoted our business to helping ETO manufacturers overcome this challenge. Through our deep knowledge of Business Central and the right software extensions, we help you maintain a clear visual of your production load at all times. Our solutions enable you to keep communication and data-sharing flowing freely across your value chain, so all parties are in the loop. Get in touch

with us today to learn more.

Share

Tweet

Share

Mail

Sign Up for Email Updates

Thank you for signing up for email updates!

Oops, there was an error sending your message.

Please try again later

Please try again later

© 2024

All Rights Reserved | DSWi