Blog Post

Overcoming Cost Challenges in Engineer To Order Manufacturing

AJ Ansari • April 16, 2024

Engineers in engineer-to-order (ETO) companies have to juggle dozens of project components in order to successfully design a product that meets a customer’s unique need. From deadlines to manufacturability to capacity to cost, every aspect seems to hold a priority. In this balancing act, too often designing for cost is left by the wayside—compromising ETO profitability.

Read on to learn why this common cost problem occurs and what ETO manufacturers can do about it.

The Design-to-Cost Problem in ETO

It’s easy to see why designing for cost gets left out of the equation in ETO environments. Engineers already have several other considerations to take into account:

- They need to design a product from scratch, with no blueprint or template, that fits the customer’s exact needs.

- Creating the right solution also has to be doable on the customer’s desired timeline.

- The product has to be manufacturable either through in-house capacity or outsourced vendors.

Once an engineer meets these requirements, there’s always the chance that the product won’t be cost feasible. It’s common for engineers to prioritize these needs before cost because these factors inform the very steps that go into manufacturing the product. But ETO companies need to keep cost in mind throughout the design process—a difficult task when so many other considerations have to come first.

The capacity conundrum is also linked to the design-to-cost problem in that accurately forecasting production capacity —whether you’re manufacturing in house or outsourcing to vendors—supports your ability to estimate cost feasibility. Without insight into capacity, your ability to see true costs is further muddied.

Both the design-to-cost problem and the lack of visibility into capacity are surmountable with the right technology.

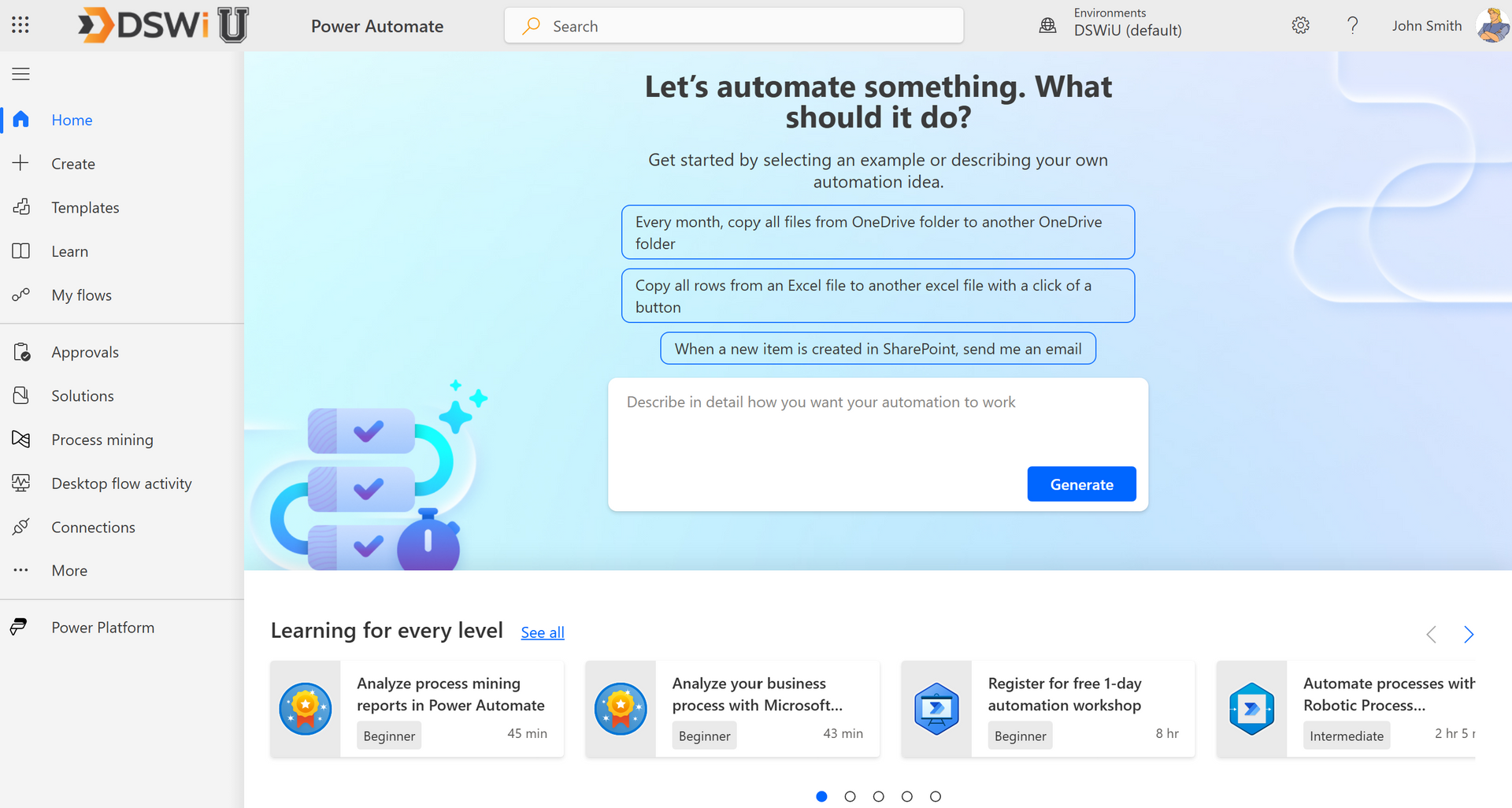

Keep Costs Clear with ERP Software and Extensions for ETO

Communication and sharing the right data among engineers, production managers, supply chain managers, and other stakeholders are the keys to determining cost feasibility. This information-sharing is possible through enterprise resource planning (ERP) technology—customized with the right extensions for ETO environments.

These solutions allow you to share cost data, lead time information, and other factors that impact every stakeholder in the value chain. For example, when stakeholders can see historical data about similar projects done in the past—including information like assembly requirements, what the lead time was, how much it cost, and more—they can extrapolate what’s needed for the current project. This data also allows manufacturers to predict profitability.

ERP systems like Microsoft Dynamics Business Central attempt to provide visibility into aspects of job costing and the impact of jobs on manufacturing capacity. For instance, many ETO companies use the jobs module within Business Central—which is excellent for managing jobs—but there are gaps when it comes to linking ETO requirements with their upstream sources of supply such as manufacturers and suppliers. This is where working with an experienced technology partner who can recommend the right software extensions is vital.

Technology consultants like DSWi bring expertise in both ETO and ERP to the table. We are familiar with the constant cost feasibility challenge in ETO environments, and we’ve helped ETO manufacturers overcome this problem with the right software. We help you implement extensions that fill the gaps of ERP systems like Business Central and its jobs module. Armed with the right solutions, ETO manufacturers can share data across the value chain, communicate effectively with all stakeholders, keep all relevant parties in the loop on cost and lead time, and fulfill the customer’s request on deadline and within budget.

Get in Touch with the Experts at DSWi

We’d love to learn about your business and offer our deep ETO experience to give you new visibility into costs. Reach out today to ask us any questions.

Share

Tweet

Share

Mail

Sign Up for Email Updates

Thank you for signing up for email updates!

Oops, there was an error sending your message.

Please try again later

Please try again later

© 2024

All Rights Reserved | DSWi