Overcoming Supply Chain Current Challenges Using Best Practices in a Post-Pandemic World

In today's rapidly evolving business landscape, the importance of a resilient and agile supply chain has never been more evident. The COVID-19 pandemic has thrust the supply chain and logistics industry into the spotlight, revealing both vulnerabilities and opportunities for innovation. At DSWI, we are at the forefront of addressing these challenges, drawing on decades of industry experience to guide businesses through these turbulent times.

The pandemic initially led to a significant downturn in demand, leaving supply chains with pre-COVID levels of inventory and capacity. However, as economies began to reopen, we witnessed a surge in demand that many industries were unprepared for. This post-pandemic demand flux, coupled with labor challenges and constrained shipping capacities, has underscored the need for strategic adjustments in supply chain management.

There are six critical areas currently shaping supply chain dynamics:

- Manufacturing : The sector faces hurdles due to material and labor shortages, necessitating innovative solutions to maintain productivity.

- Logistics : Challenges such as freight cost fluctuations and port congestion have highlighted the importance of efficient logistics strategies.

- Inventory Management : Volatility in inventory levels post-pandemic calls for more sophisticated forecasting and planning tools.

- Market Volatility : Businesses must navigate the complexities of fluctuating market conditions and pricing pressures.

- Labor Market : The shifting labor landscape requires companies to adapt to new realities in workforce management.

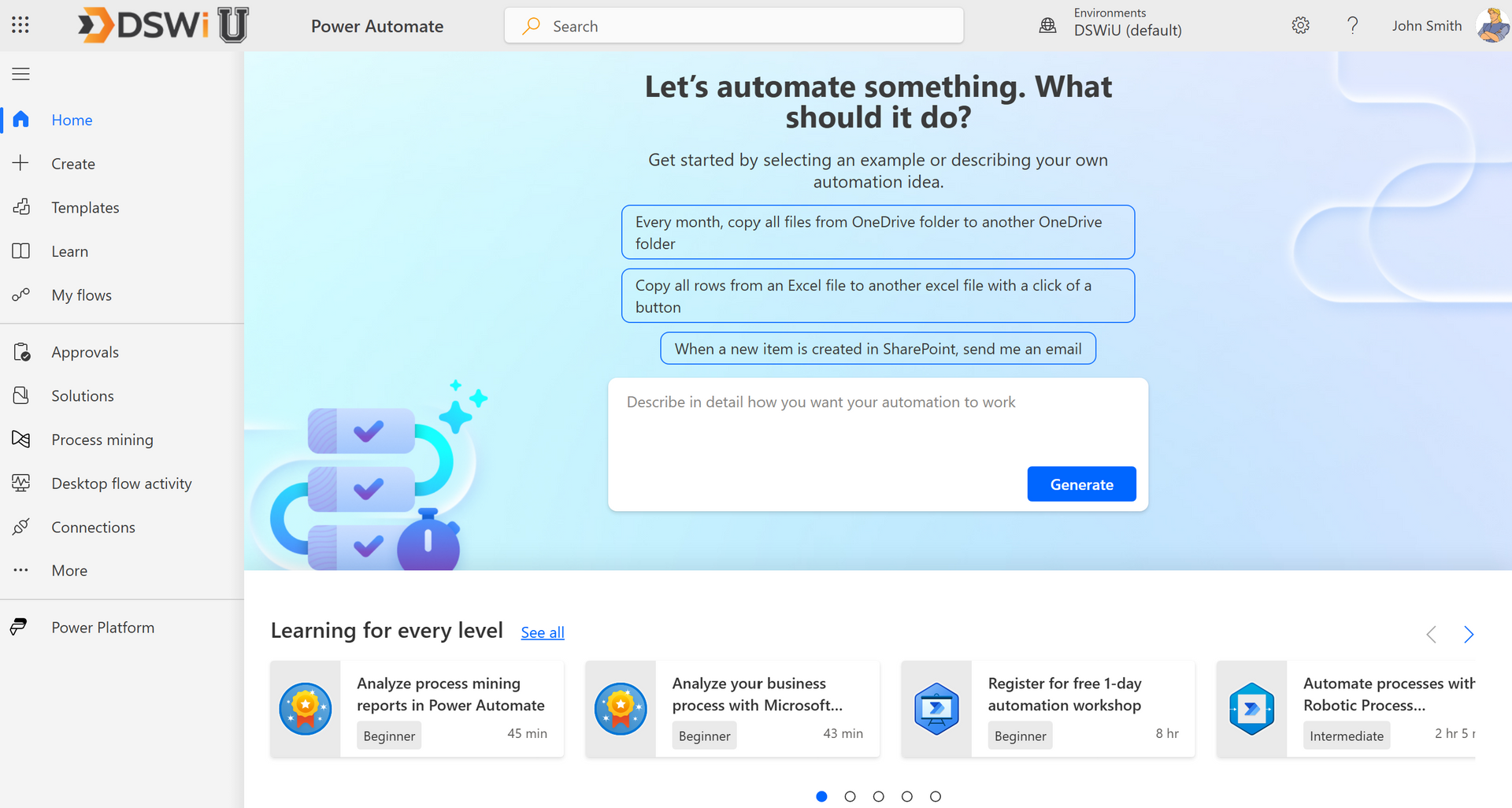

- Technology : Rapid technological advancements, such as AI driven demand planning, offer potential solutions to many of these challenges, driving the need for digital transformation in supply chain operations.

Here are some best practices you can use to start to tackle some of these challenges:

Address Logistics and Manufacturing Challenges

With logistics, the distinction between supply chain management and logistics is crucial. While logistics focuses on the movement of goods, effective supply chain management encompasses a broader range of activities, including production planning, inventory management, and customer service. Recent trends indicate a shift towards nearshoring, reducing dependency on distant suppliers and mitigating risks associated with global freight and tariffs.

Manufacturing industries face their own set of challenges, from rising commodity costs to persistent labor shortages. A strategic approach to sourcing and production can help alleviate some of these pressures, ensuring a steady supply of materials and a reliable workforce.

Tackle the N-tier Problem

One of the more complex issues that have emerged is the N-tier problem, where disruptions in the supply chain affect not just direct suppliers but extend several tiers up. This was exemplified by the semiconductor chip shortage in the auto industry, which had far-reaching consequences beyond immediate suppliers. To combat this, businesses need to enhance visibility and collaboration across their entire supply chain network, engaging with suppliers at multiple tiers to ensure stability and resilience.

Leverage Market Trends and Data

Staying informed about market trends and commodity prices is essential for maintaining a competitive edge. Tools and platforms that aggregate global market data can provide invaluable insights, enabling businesses to anticipate shifts and make informed decisions. This knowledge not only aids in strategic planning but also ensures transparency and accountability among suppliers.

Build an Agile and Resilient Supply Chain

The distinction between agility and resilience in supply chain management is critical. An agile supply chain can rapidly respond to changes in demand, while a resilient supply chain is structured to withstand unforeseen shocks. The most effective supply chains incorporate elements of both, utilizing strategies such as diversified sourcing, nearshoring, and strategic inventory management to navigate the complexities of the modern business environment.

As we continue to face the challenges and opportunities presented in a post-pandemic world, the role of effective supply chain management has never been more critical. At DSWI, we are committed to guiding businesses through these challenges, leveraging our expertise to build supply chains that are not only resilient and agile but also capable of driving growth and innovation in an ever-changing landscape.

Stay tuned for our ongoing series of insights and strategies to further enhance your supply chain operations. Geoff McCombs recently hosted a webinar discussing how Supply Chain managers can address current challenges and implement best practices to further meet arising challenges.

Sign Up for Email Updates

Thank you for signing up for email updates!

Please try again later

All Rights Reserved | DSWi