Streamlining Revenue Recognition in Engineer To Order (ETO)

Recording revenue and aligning it with expense is a unique challenge in the engineer-to-order (ETO) world. In a non-ETO manufacturing setting, it’s relatively cut-and-dry to sell items off the shelf and align costs with them. In ETO—where you have multi-month projects that incur costs before you receive any payment—it’s more difficult to see revenue, track your budget, and forecast profitability. But that’s where technology comes in.

In this blog, we look at the revenue recognition problem specific to ETO and explore how enterprise resource planning (ERP) systems like Microsoft Business Central can help.

Manual Systems Hinder ETO’s Revenue Recognition

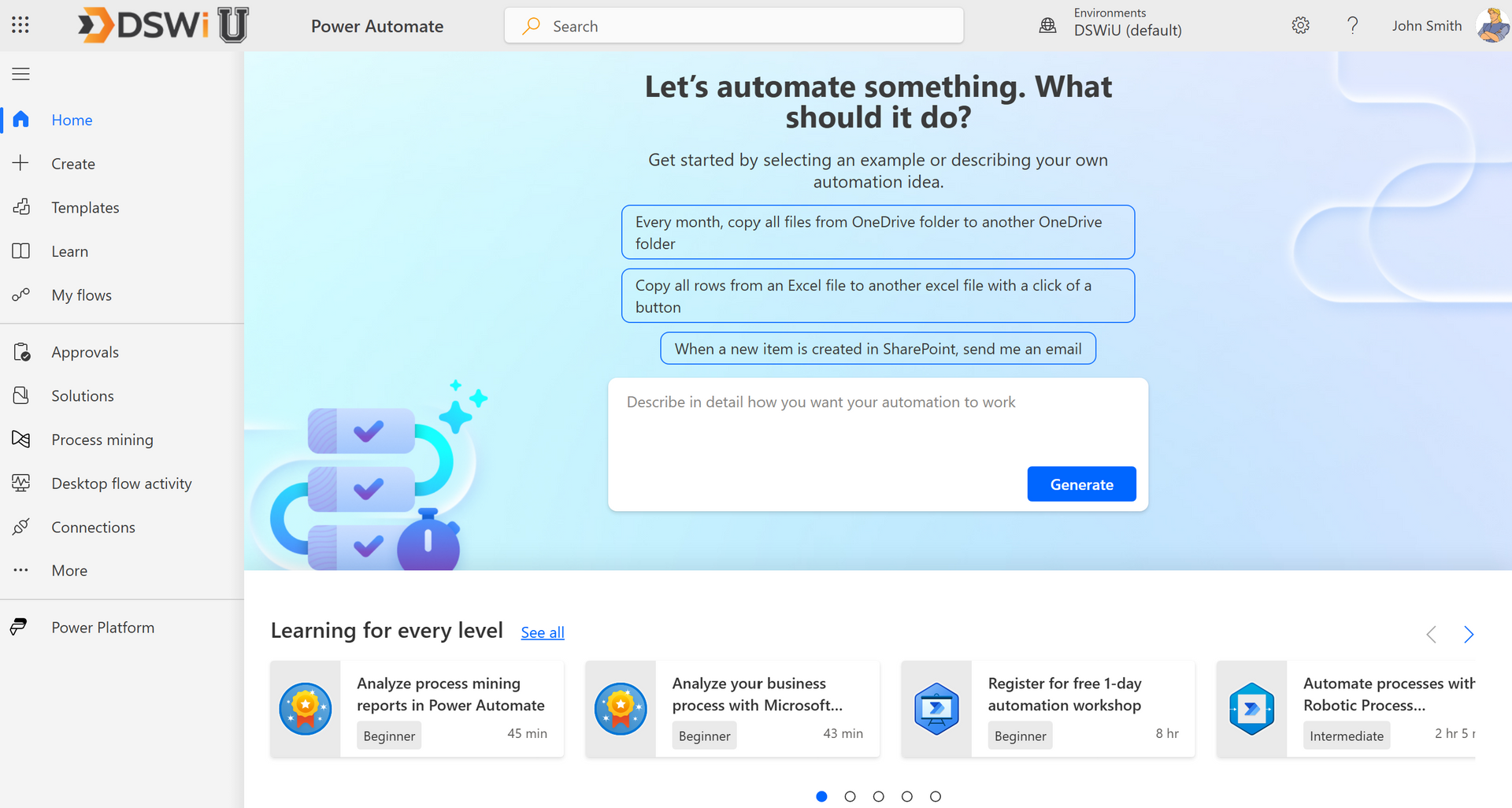

Since ETO manufacturers have more complicated project and billing structures than traditional distribution models, spreadsheets rarely support revenue recognition. Trying to align real-time revenue with costs and budget in Excel takes a Herculean effort from accounting teams. Even QuickBooks isn’t up to the task in a truly efficient way. ETO companies need solutions that reconcile costs with revenue as a project moves along—a concept in Business Central called work-in-progress.

Using an ERP system like Business Central enables ETO manufacturers to record revenue based on their Project WIP accounting methods. Percentage of Completion and Completed Contracted are the most common methods used.

For example, on Project using the Percent of Completion WIP accounting method, let’s say you have a $10,000 project that you’re going to spend $8,000 on. You’ll ultimately get a 20% margin, or $2,000, but you spend $2,000 in the first month of the project. With revenue recognition capabilities in Business Central, you can see the same percentage of revenue in that month to gain a true view of the budget consumed versus revenue. It allows you to better track your profitability along project progress, so if you start to realize you’re going over budget, you can revise costs.

Business Central also allows you to track change orders on projects to ensure revenue recognition is properly calculated throughout the project lifecycle.

Get Transparency into Real Revenue

With Business Central, ETO manufacturers get transparency into their costs and profitability, and accounting teams get automation and efficiency to better do their jobs. The system allows accounting to deliver real-time visualizations and reports on revenue alignment to the C-suite, so all relevant stakeholders get a true picture of revenue and financial health in a given moment. It also supports project management accounting techniques in the earned value space so ETO can see where they had aimed to be on a project, where they are instead, and what costs are associated with that discrepancy.

With the right technology partner, you can take advantage of other modules and sophisticated accounting capabilities like earned value so your ERP system delivers the visibility you need to make data-informed decisions about project costs. DSWi has hands-on experience in ETO industries and proven expertise helping ETO manufacturers leverage Business Central to streamline revenue recognition. We’ve seen the power of transparent reporting and clear visibility into financials—especially for ETO’s layered, complex projects. We’d love to learn about your specific needs. Get in touch with an ETO expert at DSWi to start recognizing revenue today.

Sign Up for Email Updates

Thank you for signing up for email updates!

Please try again later

All Rights Reserved | DSWi